Our products

Linerless

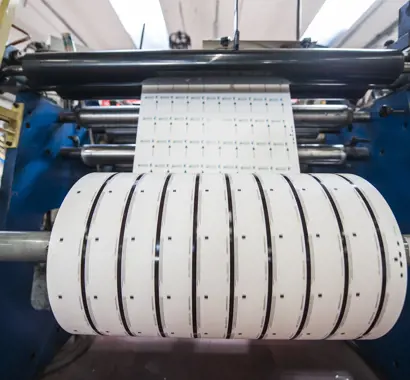

Discover Errebi: Linerless label manufacturer

Linerless is an innovative solution in the labeling industry that eliminates the traditional paper or plastic support, known as liner, usually found beneath self-adhesive labels. These labels can be applied directly to paper or film substrates thanks to its adhesive layer.

Linerless technical advantages

Linerless offers several technical and operational advantages:

- Waste reduction: in fact, it eliminates the need to dispose of or recycle liner waste, significantly reducing material waste and environmental impact.

- Increased production efficiency: Linerless labels allow for more labels per roll compared to traditional labels, reducing the number of reel changes and improving production line efficiency.

- Enhanced labeling capacity: with a greater quantity of labels per roll, Linerless rolls require fewer replacements during the labeling process, reducing machine downtime and improving productivity.

- Optimized storage space: being thinner than traditional labels, Linerless occupies less storage space, enabling more efficient label stock management.

- Flexibility and adaptability: Linerless labels can be customized to meet various labeling requirements such as size, shape, and adhesive specifications, offering a flexible and adaptable solution for different sectors and applications.

- Many different applications: Linerless by Errebi are not only adhesive and eco-friendly, but they don’t contain phenolics, and they are suitable for indirect contact with food, as well.

Overall, the adoption of Linerless leads to increased sustainability, efficiency, and flexibility in the labeling process, offering significant benefits from both environmental, operational and economical perspectives.

Technical specifications

|

Grammage |

From 70 grams to 80 grams |

|

Width |

From 50 mm to 101,6 mm |

|

Inner core |

From 8 mm to 76 mm |

|

Customization |

Logo and image printing, hotmet or acrylic glue application |

|

Paper |

Thermal paper protected without using phenolics. It’s suitable for indirect contact with food. |

|

Adhesive |

Permanent, removable, repositionable. |

Technologies

Our range of products is fully customizable thanks to a wide range of processes that we can implement.

Offset and flexography printing

Water-based flexographic printing, UV flexographic printing, and offset printing: High-quality prints for impeccable results.

Hologram and magnetic application.

We have specific technology for applying holograms and magnetic elements, as well as the ability to print magnetic ink for ticketing purposes.

Coatings

Application of a thin layer of material on the paper to enhance its strength, ink absorption, or provide specific characteristics such as waterproofing or WTR, OTR, KIT Grease barriers. Additionally, we can apply adhesives on paper, both hot melt and acrylic.

Perforation

It is a process in which small openings or regular holes are created, such as perforations, precuts, and labels.

Do you require a customized solution?

Contact us

Products with the aim of responsible forest management

Contact us fore additional information

Do you require a customized project?

We are here to bring your boldest ideas to life! With our team of creative professionals and experts, we transform your visions into tailored realities, meeting all expectations. Let your project come to life. Contact us!

Related news

Rolls for plotter? Simple! RB Wide Format

Faded receipt? Not with Sicur 15!